Proof In Performance

Ergonomic solutions are essential to having a shop floor that operates like a well-oiled machine. Dan MacLeod, a certified professional ergonomist (CPE) demonstrated this through a study he conducted using the Ergo Chief produced by Ergotronix. This study was conducted at a global manufacturing company, implementing the use of the Ergo Chief multi-axis work positioner into their operations. The before-and-after results were then compared in relation to the time and physical demands during a typical assembly procedure.

The procedure of this job previously involved applying small parts to an arched large aircraft structure. Each time a small product needed to be applied, the large structure needed to be flipped. This manual flipping motion was done 25 times throughout the application cycle. To make matters worse, the large arched aircraft part was difficult to hold, cumbersome to handle, and weighed approximately 30 pounds. Understandably this was a time-consuming and laborious process within the entire assembly of this product.

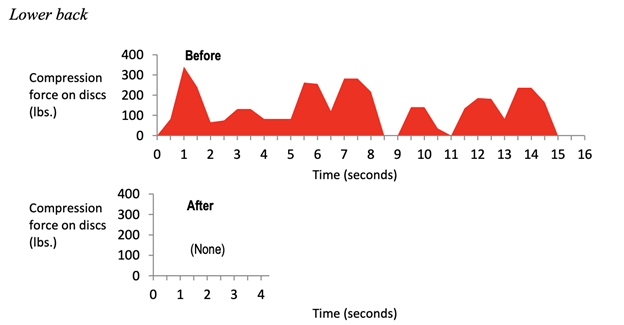

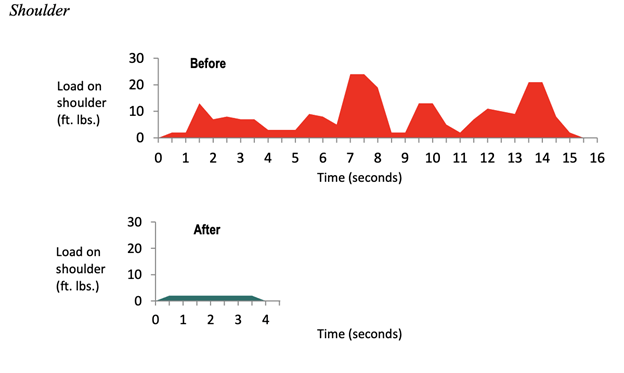

After the implementation of the multi-axis, motorized Ergo Chief work positioner, all the taxing manual flipping and positioning was eliminated, providing impressive analysis results:

Assembly time: 73% reduction

Product damage: 100% reduction (Eliminated)

Back strain: 100% reduction (Eliminated)

Shoulder strain: 92% decrease

The implementation of a suitable work positioner virtually eliminated all bodily stress during this assembly process. Not only was using the Ergo Chief less taxing on the body but it was also shown to be more efficient. Each time this particular object was flipped manually, it took 15 seconds. But, with the application of the Ergo Chief work positioner, the flip time was cut down to 4 seconds per flip. This equates to saving approximately 4.5 minutes during just this portion of the manufacturing process.

This ergonomic solution had additional positive consequences.

During the original manual assembly procedure, the product had a high potential of being dropped and becoming damaged. Such drops would result in the product needing to be repaired at the rate of approximately two hours. These time consuming, wasteful accidents were eliminated with the use of the Ergo Chief work positioner. Not only did the Ergo Chief dramatically reduce the bodily stress on employees and save incredible amounts of time, the Ergo Chief also eliminated costly accidents from this assembly process

Results like these are also attainable for you and your shop floor.

Ergonomic solutions brought to you by Ergotronix, pay dividends in multiple facets. Just like we see in this study, conducted by Dan MacLeod, implementation of suitable ergonomic solutions results in increased productivity, reduction in rework and decreased impacts on the human body, etc.