A Guide To Ergonomic Redesign

In the world of manufacturing, continuous improvement and progression are a must. But what defines progression? How are we attaining progression? In a typical workplace environment, progression may be measured as an increase in production and level of output, resulting in more revenue and profit.

Ultimately the goal is to increase profit, one of the simplest ways to do so is by ensuring ergonomic efficiency on your shop floor. Ensuring ergonomic efficiency will increase the level of output from your employees, while producing less bodily strain and less rework etc.

Below is a short list of guidelines that we can use while evaluating the shop floor.

- Assess

- Evaluate

- Investigate

- Optimize

- Utilize

ASSESS

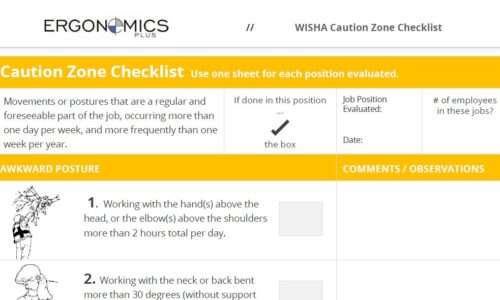

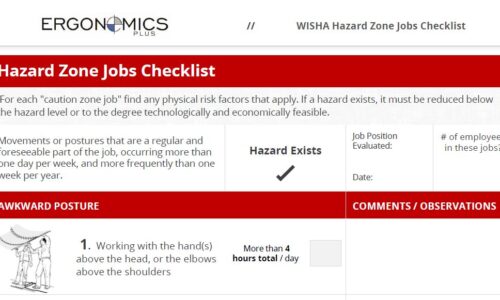

Ergonomic issues are often a byproduct of poor layout, wasteful processes, improper or inappropriate equipment, and often bad employee habits. Progressing into any shop floor re-design without understanding the basic elements can be costly, ineffective, and can incite frustration among staff. The assessment tools can take various forms, including checklists and reviews of past workplace inspection documents. Examples include checklists such as these coming from Washington State University:

EVALUATE

After completing the assessment, determine which of the identified issues are problematic and diminish the human ability to perform effectively. More often than not, there will be a clear path of prioritization based on the potential problems of each issue. For example, a heavy lifting hazard is more significant than operating at a workstation a few degrees below the optimal level.

Consult standards and guidelines to fine-tune work methods and work expectations. Both the International Organization for Standardization (ISO) and American National Standards Institute (ANSI) guide organizations on how to better configure their programs, processes, and overall design for improved safety and quality.

INVESTIGATE

See what other companies have done and are doing to mitigate their similar design concerns. By collaborating with organizations and professionals that have gone through similar processes, your company can avoid many unforeseen pitfalls by learning from the mistakes and successes of others.

It is vital to thoroughly investigate ideas while they are still on paper and incredibly easy to modify, which saves both time and money, whilst preventing potential injuries from occurring.

OPTIMIZE

Employees can only work so fast, lift so much and adjust their posture within a specific range of motion. Outside of that spectrum, special equipment and furnishings can bridge the gap. This is where optimization with technology can help reduce the frustration that comes with operating outside the limits of the human body.

An typical example of shop floor optimization would be utilizing lift tables, transport carts, and other handling devices to allows employees to complete their work tasks comfortably, at a correct ergonomic working height, without compromising safety and comfort.

UTILIZE

Utilize resources that you may already have at your disposal and don’t hesitate to also get assistance from companies that specialize in providing ergonomic remedies for the factory floor. It is vital to use both internal and external resources during a shop floor re-design.

Involve your employees in understanding the issues at hand. Such practice will promote buy-in and improve management-staff relations.