Productivity Versus Efficiency

Productivity and Efficiency

These words are often thrown around, somewhat interchangeably in the world of manufacturing and production, but what do they really mean? Furthermore, how can improvements in productivity and efficiency be measured? A quick google search or a glance through the nearest dictionary tells us that the definition of the words are, respectively:

Productivity

“The effectiveness of productive effort, especially in industry, as measured in terms of the rate of output per unit of input.”

Efficiency

“(especially of a system or machine) achieving maximum productivity with minimum wasted effort or expense.”

So, how are these words applicable and helpful to those in the industries of manufacturing and production? Well, productivity in manufacturing measures the number of units produced or net sales, relative to the input. These inputs can be broadly divided into four main categories:

- Physical capital. The physical equipment and structures workers use to create goods and services

- Human capital. The knowledge and skills that workers gain through education, training, and experience — all the practical understanding accumulated during their life

- Natural resources. These inputs are derived from nature commodities, including renewable resources (e.g. plantation forestry, solar power) and nonrenewable resources (e.g. oil, minerals)

- Technological knowledge. Technological progress within the economy. Technological knowledge can be public or proprietary. Public knowledge is openly available and used by all firms, while proprietary knowledge is secret and only known to the company that discovers it

At the simplest level, productivity is simply a measure of units of output/units of input with no regards to wasted effort or expense. But in the industries of manufacturing and production, dollars and cents are how we make sense of all our efforts to produce goods, so measuring productivity alone is not an accurate measure of the overall success of a manufacturing process. It is equally as important to understand and pursue efficiency in the manufacturing process. In layman’s terms, efficiency is the ability to produce something without wasting materials, time or energy. The idyllic scenario being that of 100% efficiency implying that no effort or expense is wasted. The reality where no screws are dropped and every weld bead is perfect is unrealistic because human beings make mistakes. However, human beings aided by mechanical solutions show marked improvements in efficiency over their counterparts with man-power alone. In manufacturing, we should continually seek to improve our efficiency to improve the quality of our products and to increase our returns, and these improvements can be achieved through, for example, ergonomic solutions.

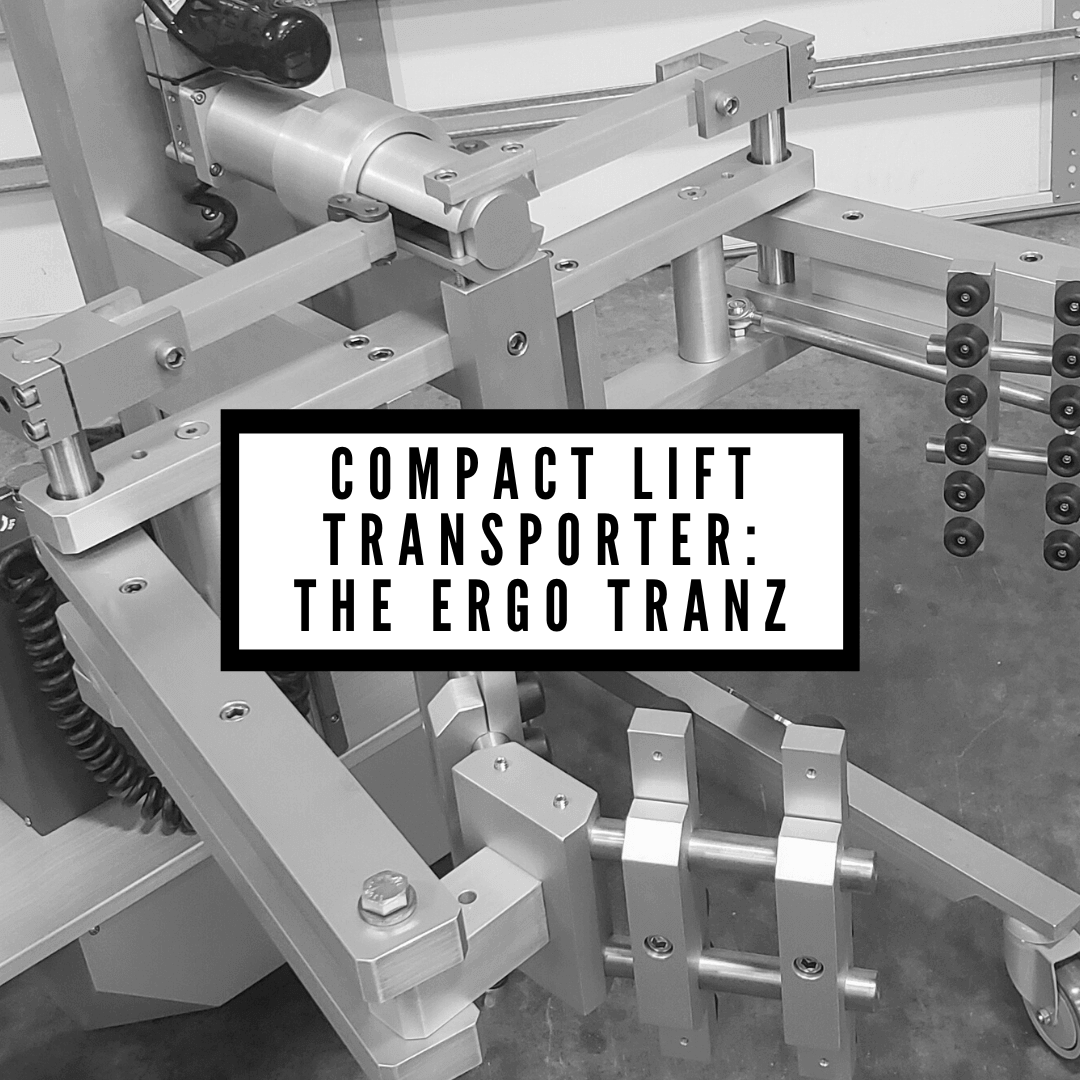

Ergonomic technology can give your workers an incredible mechanical advantage over their unassisted counterparts. For example, an Ergo Tranz compact lift transporter can support loads up to 600 lbs, and move those loads with ease from location to location. This transporter requires one operator to use as it is light weight and allows operation of attached end-effector from a single hand remote. The lifting and transportation of an object weighing up to 600 lbs without assistance would require multiple operators to exert themselves, risking injury, and would never be completed with the level of precision that the Ergo Tranz achieves. Ergonomic solutions benefit all parties involved; the worker in matters of safety.

Is it possible to simultaneously become more efficient and productive? Absolutely, it is possible to improve efficiency and productivity simultaneously. In fact, all the ergonomic solutions offered by Ergotronix are engineered to do just that. Ergotronix full line of products are designed to eliminate extraneous efforts while maximizing productivity. In practical application, these benefits can be manifested in decreasing physical labor efforts, decreasing production time, increasing quality, and many others. An excellent example of increased productivity and efficiency can be found in a testimonial given to us by an Ergotronix customer. After implementing an Ergotronix work positioner in their shop, they said:

Applying Ergotronix positioning devices have been proven to be a huge success at (our company). The original operation required up to four mechanics. Today the task can be performed with just one operator.

This is one of many instances where Ergotronix products have resulted in increases in both efficiency and productivity. Eliminating strain, decreasing procedure time, decreasing the number of operators necessary and many other benefits come from implementing ergonomic solutions into the design of a shop floor. Whether it be work positioners, lifts, transporters or any other ergonomic solutions, Ergotronix can help you strike that balance between productivity and efficiency on your shop floor.