Identifying Ergonomic Hazards in the Industrial Workplace

Key Takeaways

- Proactive ergonomic hazard identification prevents injuries through workplace analysis.

- Observable Risk Indicators: Awkward postures, excessive force, repetitive motions, contact stress, and vibration exposure are visible signs of ergonomic hazards.

- Quantitative tools like force gauges and posture analysis software objectively document hazards, moving beyond subjective observation.

- Employees provide critical insights often missed by safety professionals during ergonomic assessments.

- Hazard management prioritizes risks by severity, exposure, and population to maximize injury prevention.

Ergonomics by definition, is the study of people’s efficiency in their working environment. In a practical sense, ergonomics refers more to the observation and optimization of a work environment to better suit the human body and by implementing aids in the work process that decrease worker fatigue and injury, while increasing efficiency, productivity, and comfort.

It can be easy to see how designing workspaces to be more ergonomically friendly pays huge dividends for companies that choose to do so. However, ergonomic solutions can only be of value when they are implemented and used correctly and mitigate the potential for workplace hazards.

What Are Ergonomic Hazards in the Workplace?

Ergonomic hazards in the workplace include things that may seem fairly harmless initially but threaten to become larger issues if not addressed properly. Activities that require employees to exert strain and physical effort, such as heavy lifting, carrying, and repositioning objects or performing other physically demanding tasks repeatedly can today be addressed and corrected by implementing available ergonomic aids, tools, or products.

The Ergo Tranz helps eliminate many situations where the employee would need to carry, bend, twist, and lift.

Even if there are no obvious physically strenuous tasks on your shop floor, this doesn’t mean there aren’t ergonomic issues present. Repetitive motions, prolonged exposure to heat, cold, loud noises, or vibrations, are all examples of ergonomic issues that all deal with implications to the human body other than just physical exertion.

To enhance efficiency and safety in the industrial workplace, Ergotronix provides a range of tailored solutions. These solutions are designed to address the specific needs and challenges faced by businesses operating in the industrial sector, ensuring a safer and more productive work environment.

The Ergo Tranz Compact Lift Transporter

The Ergo Tranz is designed to significantly reduce instances requiring employees to engage in physically demanding tasks such as lifting, manipulating, or carrying heavy items. This innovative tool aims to improve workplace safety and efficiency by minimizing the risk of injury associated with these strenuous activities.

Ergo Tranz Features

- Lift and transport workload up to 650 lbs

- Compact, light-weight hand truck

- Heavy Duty Battery power for lift and other desired powered work manipulations

- Eliminates body strain of manual work effort

- Adaptable to a variety of standard and custom end-effectors

- Built-in safety features

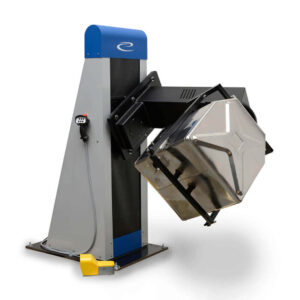

The Ergo Force Motorized Work Positioner

The Ergo Force is specifically designed to securely manipulate heavy loads with ease. This innovative tool allows for full 360-degree rotation, lifting, and turning of work objects during the work process. Its robust design and functionality make it an essential addition to any workspace aiming to enhance efficiency while prioritizing worker safety and comfort.

The Ergo Force is one of four ergonomic work positioners that secures heavy loads. It can rotate and twist heavy objects while being worked on to eliminate strain, awkward positions, and frequent heavy lifting.

Ergo Force Features

- Ergonomic motorized multi-axis work positioner/weld positioner

- 360º rotation, height, and tilt positioning

- Support workloads up to 1,500 pounds

- 2- or 3-axis configuration

- Precise electronic control system

- Built for heavy-duty factory applications

- L-shaped arm allows for turning the attached product up-side-down

- Optional rotary ground system

- Turn table allows for ease of fixturing

While the human body is a biological marvel in and of itself, this does not mean it is indestructible. It is important to remember that the human body has limitations and that modern ergonomic solutions are designed to bridge and cater to those limitations. Therefore, when an ergonomic workplace issue is identified, it’s important to address it in a timely fashion. If left unresolved, an initial minor issue can quickly or over time snowball into becoming a serious problem.

The nature of ergonomics is that solutions are oftentimes simple. If the work is too physically demanding, consider implementing equipment that can eliminate the human exertion elements. If there is an environment with potentially harmful stimuli to the workers, provide personal protective equipment to ensure their safety at all times. The possibility for ergonomic improvements to the workplace is virtually limitless. Next time you find yourself on the shop floor, ask yourself, “Is there something more I can do here?” Chances are, there will be, and your shop floor personnel will thank you with improved performance and quality of work.

Ready to Eliminate Ergonomic Hazards in the Workplace

If you’re interested in discovering how Ergotronix can transform your industrial workplace into a safer and more enjoyable environment for your team, we invite you to get in touch with us. We’re here to provide you with comprehensive details, including in-depth product datasheets and detailed 3D CAD files, to help you make an informed decision. Our solutions are designed with your workers’ safety and satisfaction in mind, and we’re eager to show you how our innovative products can make a significant difference. Contact us today for more information and take the first step towards a better workplace.