Multi-Directional Conveyor Rollers

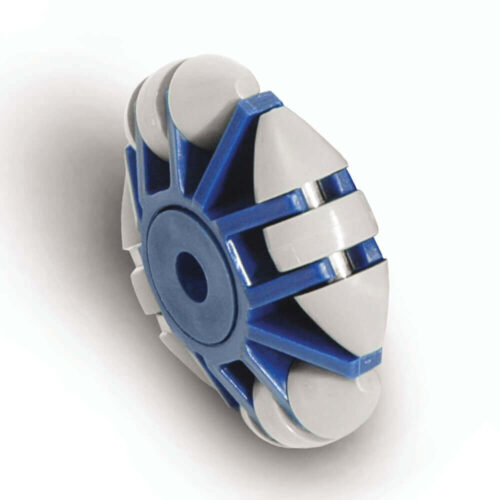

Ergo Roll®

Multi-Directional Conveyor Rollers

Transfers and turns material smoothly and safely in any direction.

- Use in gravity or motorized conveyor configurations

- Lego type roller building blocks

- Easy integration into new or retrofit of existing conveyors

- Single roller or duplex roller modules

- 12.5 lbs to 90 lbs load capacity per roller

- Available for most common conveyor axles.

- Self-lubricating material

- Dry and wet sort and transfer applications

- Omni-directional roller

Product Description

Move and transfer product easier with the Ergotronix Ergo Roll® multi-directional conveyor rollers. Due to its unique design, the Ergo Roll® is more versatile than traditional ball transfer rollers or skate wheels.

The Ergo Roll® multi-directional function and agility is structured around the principle of mounting four free turning football shaped rollers in a 90 degree staggered pattern around the perimeter of a main wheel hub. This arrangement provides a total of five rotational axles per each wheel assembly.

In a single or duplex wheel configuration, where two wheels are placed side-by-side, a total of nine individual rotational turning axles allow for flawless multi-directional conveyor movement. You can smoothly turn or transfer products or materials in any direction, whether your application relies on gravity or motorization for movement.

Made from non-marring self-lubricating plastics material, the Ergo Roll®, eliminates scratching of a finished product surface and works equally well in dry or wet applications Its large load-carrying surface area, diminishes product indentation. The open construction allows for particles or dirt, in the use application, to gravitate through the roller structure, without causing binding or lock-up of the multi-directional roller function. The Ergo Roll® conveyor roller doesn’t require maintenance or lubrication to provide a worry-free sort and transfer service life. Available for most common axle configurations, the Ergo Roll® provides for easy installation into existing or new gravity or motor driven conveyor applications, where material or packages need to be smoothly and easily transferred, sorted or turned in any direction

Of all the rollers we have purchased, we have had zero failures and they all still work as they did the day they were installed.

Scott Berry

Vesuvius

More Testimonials

Our assembly employees found that if they apply the Ergo Roll® with a graphite lubricant, the mortar being used in our assembly process would not stick to the rollers and could easily be removed after it dries. Of all the rollers we have purchased, we have had zero failures and they all still work as they did the day they were installed.

Scott Berry, Engineering

Vesuvius

We use the unique ergonomic rollers in many of our shop applications. We find them working great for manipulating our tires.

David Eole, Corporate Ergonomic Manager

Michelin

Less Testimonials